Step 1: Order Receipt & Farming Zone Activation

The process begins with receiving customer orders, including specific requirements on quantity, size, delivery schedule, and transportation method. This information is verified and transmitted to affiliated farming zones to initiate sourcing activities in accordance with committed standards.

Step 2: Traceability Verification & Input Quality Assessment

At the farming zones, KLC Seafood’s technical team conducts inspections of farming records, cultivation logs, health status, and raw material traceability. Once laboratory test results meet required standards, the procurement team proceeds with on-site biological assessment and verification of aquaculture conditions. Only seafood that fully complies with food safety, quality, and traceability requirements is approved for procurement and transferred to subsequent stages.

Step 3: Raw Material Transportation

After procurement, raw materials are weighed, graded by size, and stored in specialized containers filled with clean seawater and continuous oxygen supply. Transportation to processing facilities is carried out using dedicated vehicles, ensuring product quality and vitality are maintained prior to processing.

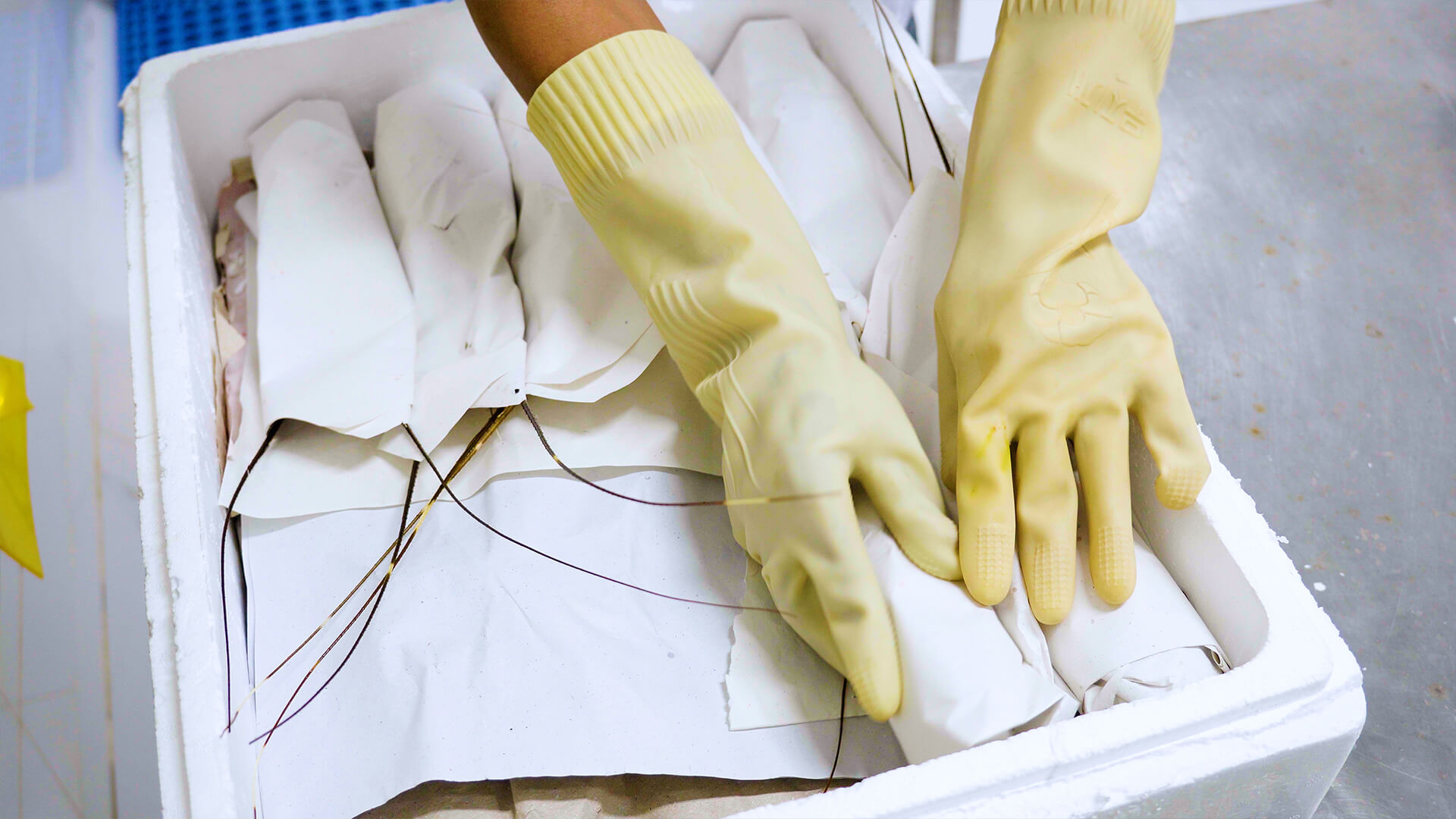

Step 4: Quality Control at Processing Facilities

At the processing plant, the QA/QC department conducts a comprehensive inspection of each batch based on raw material condition, food safety criteria, and traceability documentation. Processing, temporary holding, and handling stages are strictly monitored under the HACCP food safety management system, ensuring compliance before proceeding to the next stage.

Step 5: Processing & Packaging by Transportation Method

For air freight exports, seafood is processed according to specialized procedures to maintain optimal vitality prior to packing, combined with oxygen injection and packaging compliant with international transportation standards. For land transportation exports, shipments undergo a final inspection covering quality, documentation, and export conditions before warehousing, ensuring full compliance with destination market requirements.

Step 6: Safe & Transparent Export

All shipments are continuously monitored throughout the export process until delivery to international partners. Export documentation, certifications, and traceability data are fully completed and securely archived, ensuring quality consistency, regulatory compliance, and transparency throughout the cooperation process.

Every process at KLC Seafood is designed and operated with strict standardization and consistency, ensuring quality management, food safety, and product reliability. This serves as the foundation for KLC Seafood to meet export market requirements and build long-term trust with international partners.

KLC Seafood has developed a network of linked aquaculture zones with a total area of 556 hectares across Cam Ranh, Van Ninh, and Song Cau – regions characterized by stable natural conditions, suitable water environments, and high ecological regeneration capacity. This collaborative aquaculture model enables KLC Seafood to maintain strict input quality control and ensure stable supply capacity for export markets.

SEAFOOD SOURCING

KLC Seafood focuses on high-value seafood species, with live lobster and live spotted babylon snails as its core product lines. Seafood is selected based on stringent criteria, including biological health, uniform size, high survival rates, and strong adaptability throughout harvesting and transportation.

Seasonal selection, combined with controlled stocking density and environmental conditions, ensures consistent quality, standardized appearance, and high commercial value, meeting the technical requirements of export markets.

FARM MANAGEMENT

Aquaculture zones are managed under strict control protocols, including continuous monitoring of water environment, stocking density, and growth conditions.

This management system minimizes risks, maintains consistent quality, and ensures clear traceability throughout the entire farming process.

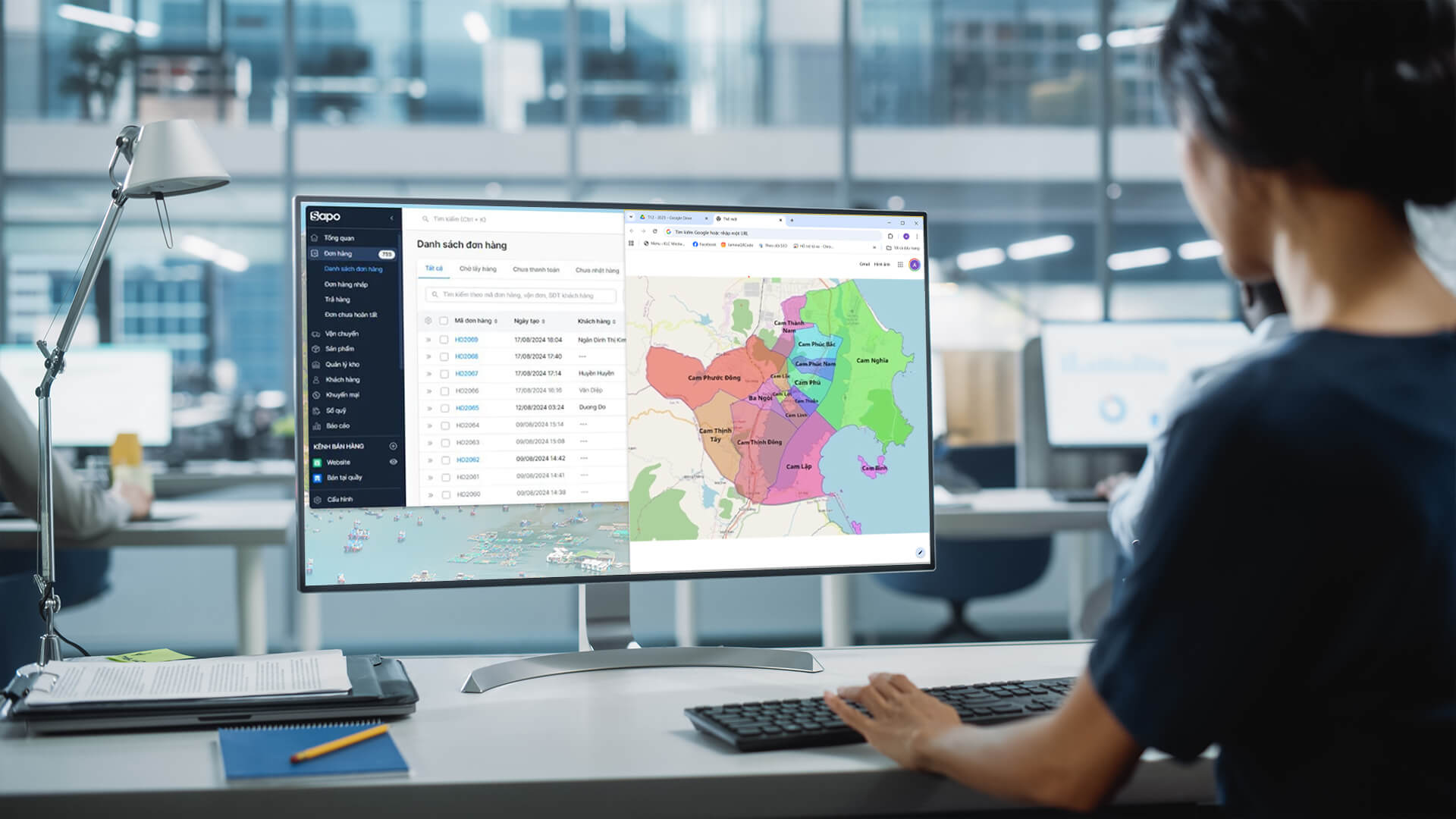

OPERATIONAL SYSTEM

KLC Seafood’s aquaculture and processing activities are synchronized and standardized in accordance with quality management and food safety principles, ensuring consistency across all products.

On this foundation, KLC Seafood remains committed to sustainable development, balancing production efficiency with environmental responsibility and building long-term, cooperative value with export partners.